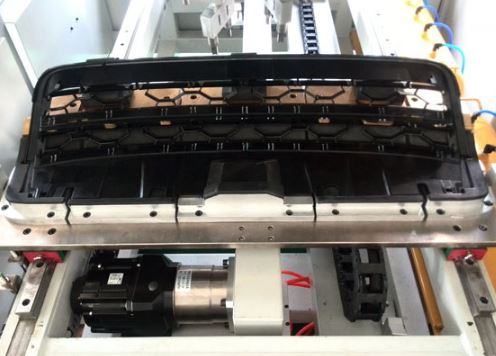

The car grille welding machine is also called the car air intake grille money decorative plate welding machine. The ultrasonic interior puncture process is used to weld the grille interior parts, and the automatic slide rail tooling and the multi-head ultrasonic system are used for ultrasonic welding to realize automation.

Ultrasonic puncture welding will cause some damage to the car grille, and the use of imported high frequency ultrasonic systems will reduce it.

Automotive grill welding machine welding advantages:

Multi-head ultrasonic system riveting (ultrasonic mother-child welding), solder joints are firm and reliable

PLC control, safe, convenient, no mistakes, can improve the efficiency of welding

It is equipped with imported safety grating to ensure the safety of employees. It has two-button control and emergency stop button, which improves safety and practicability.

Parts and electronic control components are imported parts, with good quality assurance, high operating performance and safety.

Using servo drive system, tank chain, automatic rail device

The automobile grill welding machine completes the welding process through a non-standard multi-head ultrasonic welding system. The equipment switches the welding work between the welding heads through three inlet generators, and the welding operation is completed stably and quickly. The welding requirements of the customer, the welding unit of this equipment is controlled separately and independently. Each welding head can be operated or adjusted independently to meet different needs. In order to ensure the accuracy of the welding station, the servo is used to drive the mechanism last night, and the positioning is accurate. The equipment is easy to operate, the workers only need to swing and put, the welding process is fully automated, and the welding process of one piece is about one minute. The equipment is used to protect the surface of the welding surface to prevent the surface of the painting from being scratched.

Contact Person: Ms. Hogo Lv

Tel: 0086-15158107730

Fax: 86-571-88635972