The automobile A-pillar plastic piece flat welding machine is to use the ultrasonic technology to weld the A-pillars to each other. It is controlled by PLC controller, and the multi-head ultrasonic mother-child welding is used for one-time welding. The A-pillar generally uses the material to weld better, and the welding strength reaches the customer’s requirement.

Automotive A-pillar plastic parts flattened welding samples

The overall fastness of A-pillar splicing parts meets customer requirements

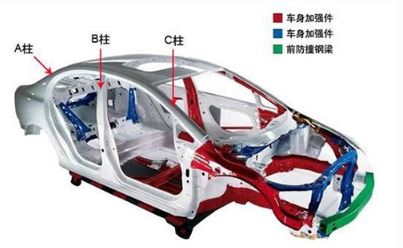

The A-pillar refers to the column between the windshield and the front door.

Automobile A-pillar plastic parts are combined with the welding bottom mold tooling to prevent the paint from falling off.

The automobile A-pillar plastic flat welding adopts 20K sub-welding head, and the system can follow the customer's request to adopt domestic or imported system.

Automobile A-pillar plastic parts multi-head ultrasonic welding machine features

1. Safety device such as safety grating, emergency stop button, honey alarm, etc.

2. Multi-head ultrasonic system, sub-weld head, control of ultrasonic welding head through electric box switching

3. Each cylinder individually controls a single ultrasonic welding torch, and the cylinder slides

4. Using PLC control system to control ultrasonic welding time, curing time and other parameters

5. The equipment adopts rapid mold change structure, and the specific parameters of the equipment are designed according to the requirements of the customer for non-standard design.

Contact Person: Ms. Hogo Lv

Tel: 0086-15158107730

Fax: 86-571-88635972